Welding is a crucial technique used in numerous industries, from construction to automotive manufacturing. It involves the process of fusing materials, typically metals, by heating them to their melting point and often applying pressure to form a solid bond. There are various methods of welding, each with its distinct characteristics and applications. Understanding the types of welding is vital for selecting the right process for any project. In this article, we will explore four of the most common types of welding, including their benefits, challenges, and best use cases.

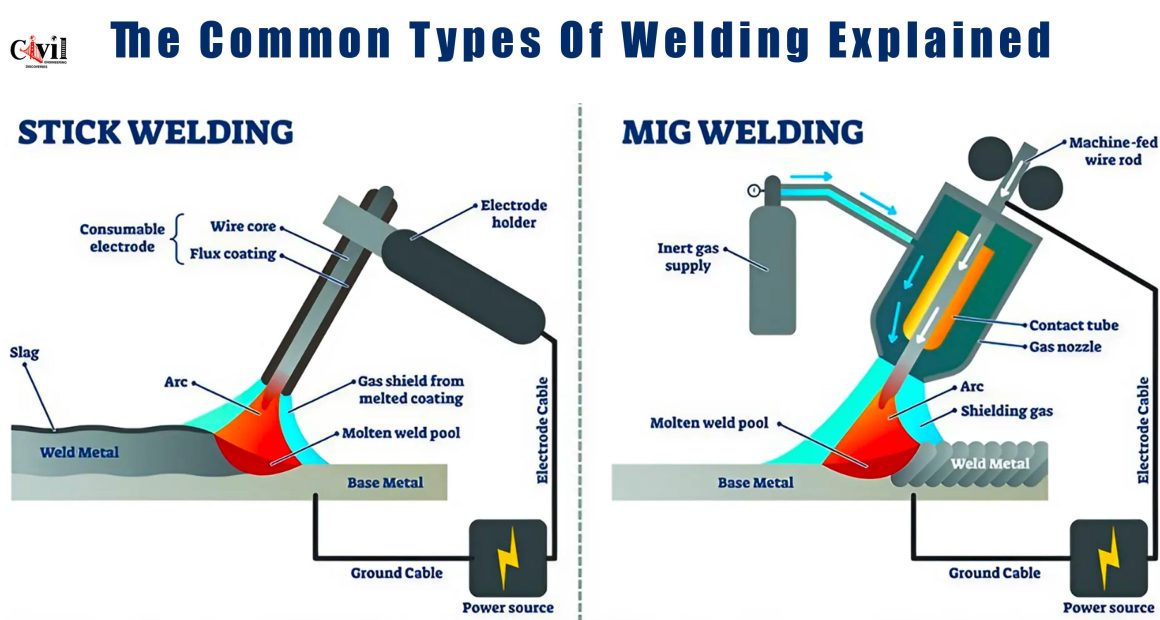

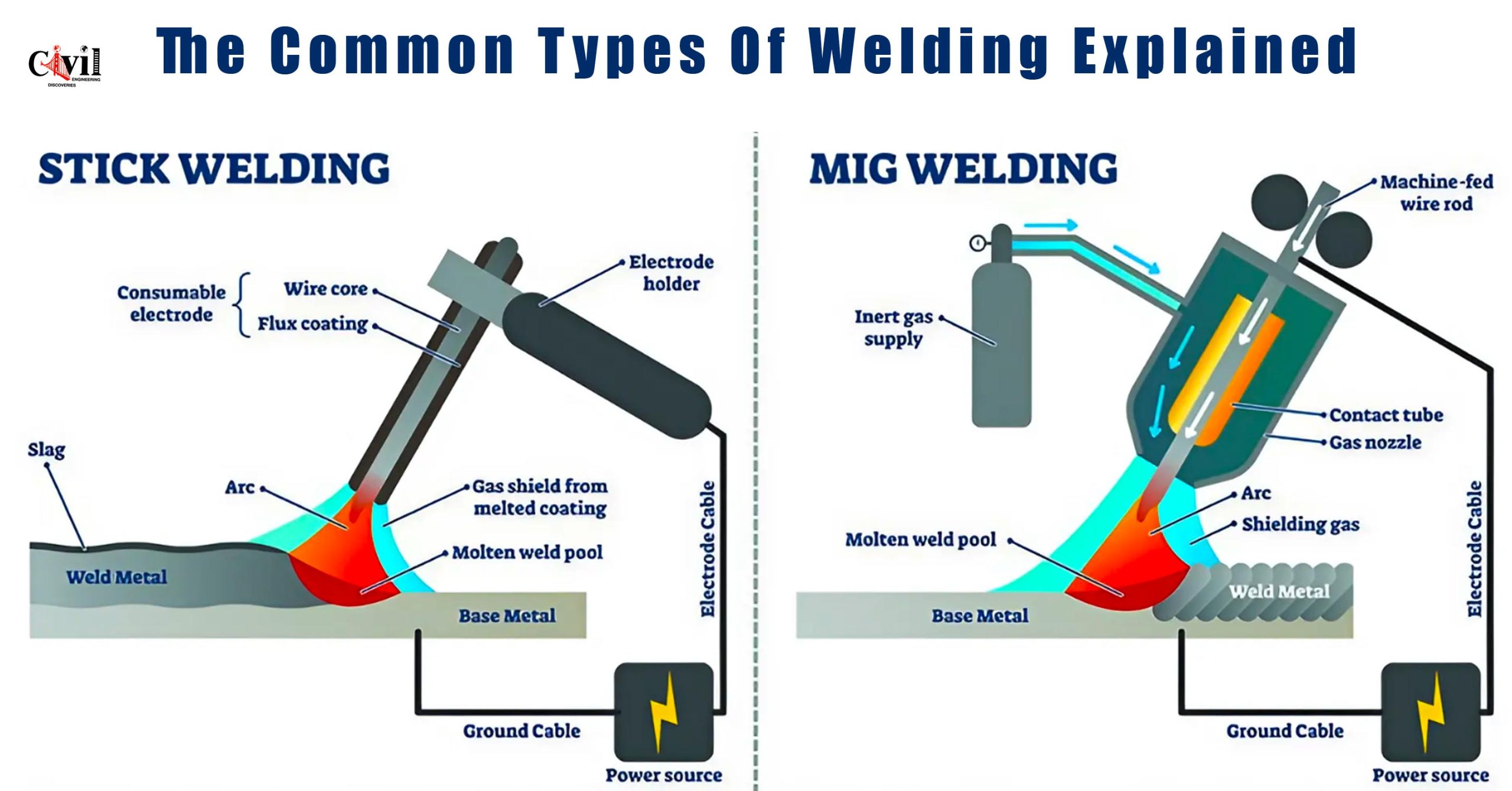

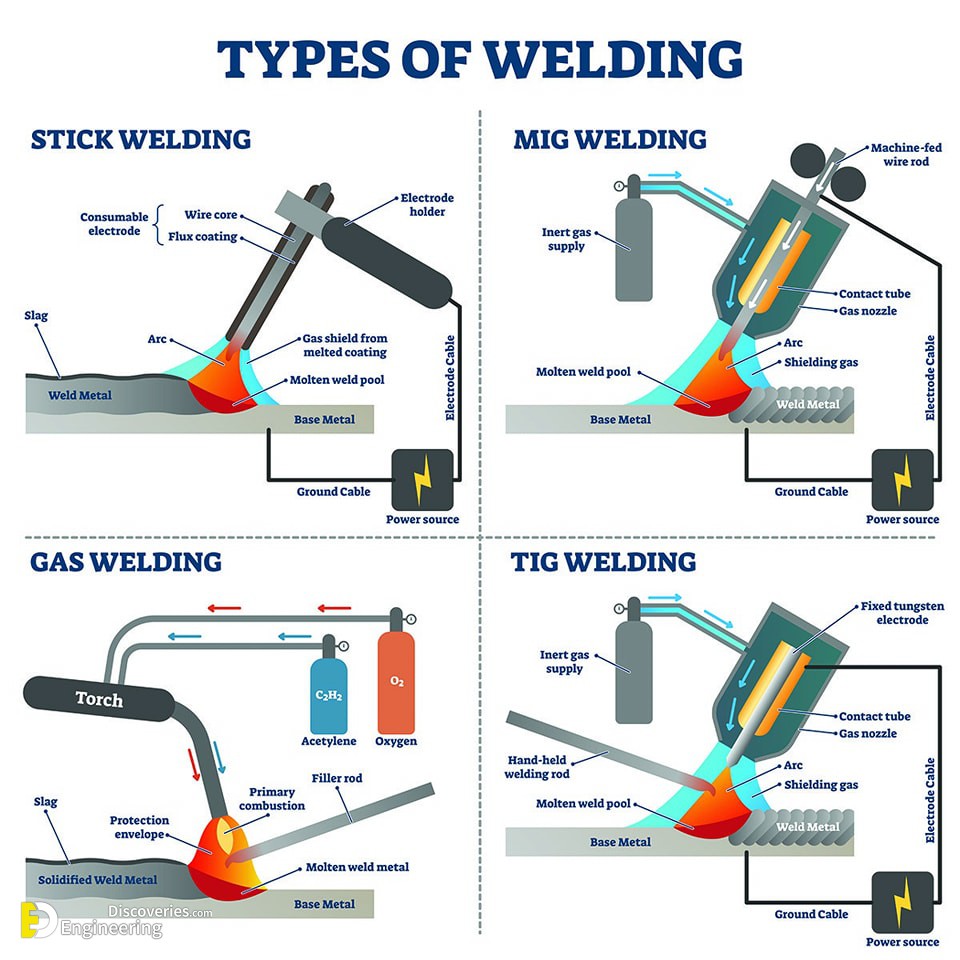

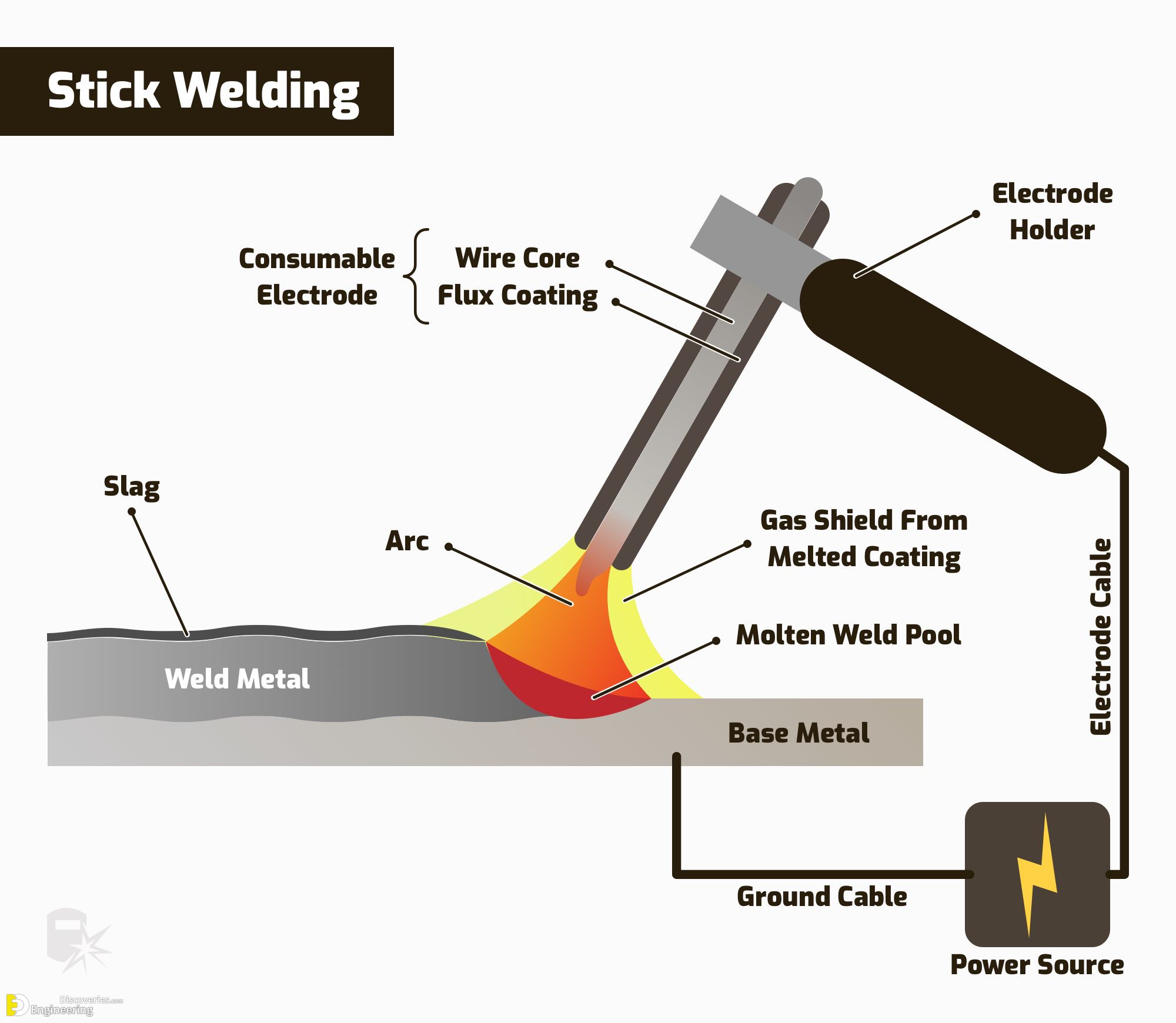

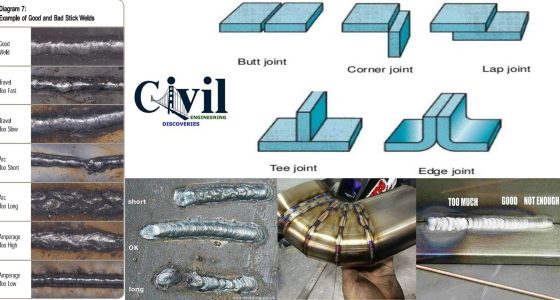

1. Stick Welding (Shielded Metal Arc Welding – SMAW)

Stick Welding, also known as Shielded Metal Arc Welding (SMAW), is one of the most widely used and oldest welding techniques. It involves the use of a consumable electrode coated in flux to lay the weld. The electrode, or “stick,” creates an electric arc between the stick and the metal workpiece, which heats the metals to their melting point. As the metals melt, the flux coating on the electrode disintegrates, producing a protective gas shield that prevents oxidation.

Advantages of Stick Welding:

- Versatility: Stick welding can be performed in a variety of environments, including outdoor settings, making it ideal for fieldwork.

- Cost-effective: The equipment for stick welding is generally more affordable than other methods.

- Simplicity: It requires less technical skill, making it accessible to hobbyists and professionals alike.

Challenges:

- Slower speed: Stick welding tends to be slower than some other techniques, which can increase production time.

- Post-weld cleanup: The slag left after welding requires cleanup, adding an extra step to the process.

Applications:

Stick welding is often used in construction, maintenance, repair, and pipeline welding. It works well on thicker materials, particularly in outdoor environments where wind and other elements might interfere with other welding processes.

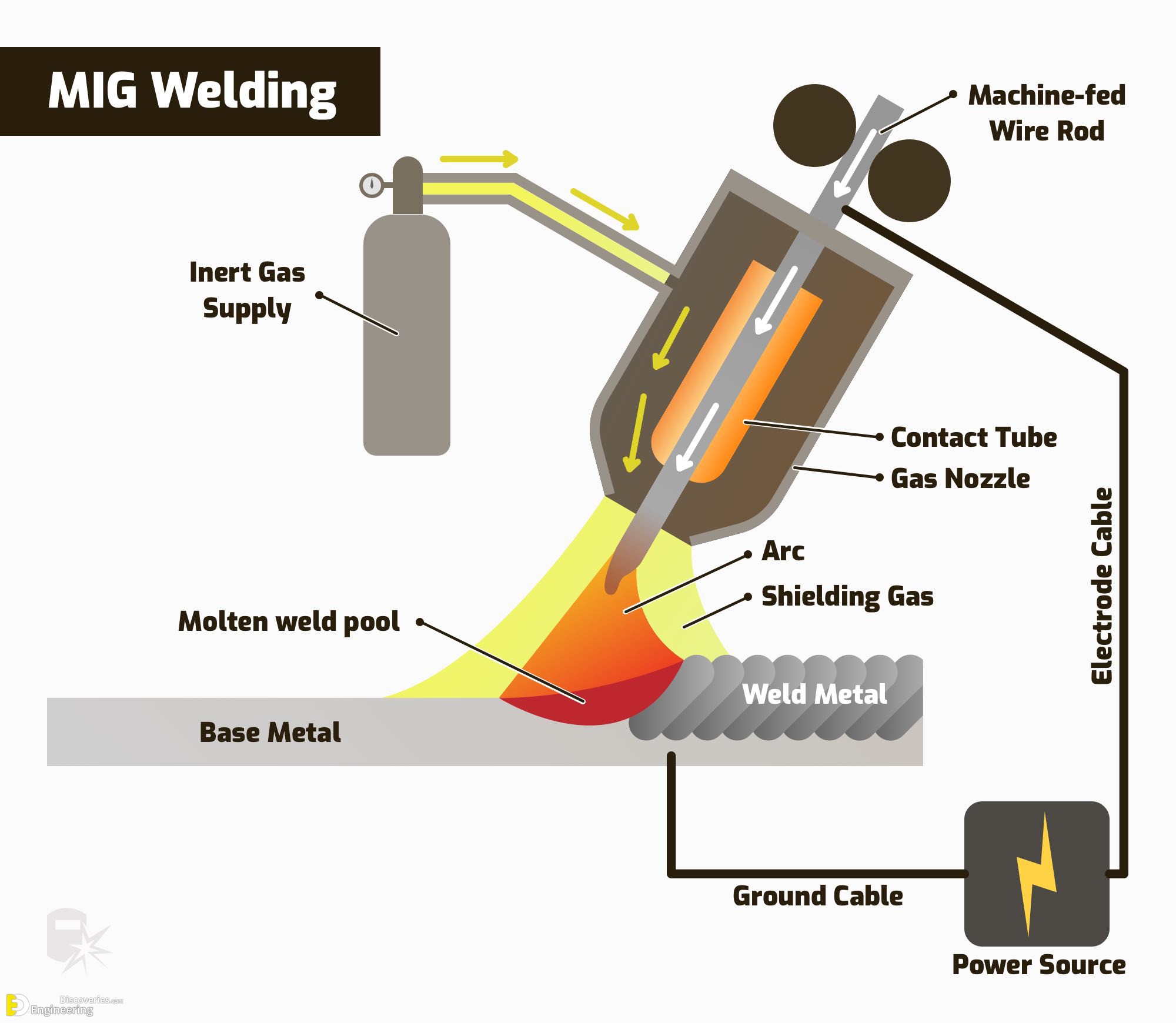

2. MIG Welding (Metal Inert Gas – GMAW)

MIG Welding, or Gas Metal Arc Welding (GMAW), is a faster and more efficient welding process compared to stick welding. In this process, a continuous wire electrode is fed through a welding gun, along with a shielding gas (typically a mixture of argon and carbon dioxide), which protects the weld pool from contaminants.

Advantages of MIG Welding:

- Higher speed: MIG welding can be performed quickly, making it suitable for high-production environments.

- Cleaner process: There is less spatter and slag, which means less post-weld cleanup is required.

- Ease of automation: MIG welding is easily automated, which makes it popular in industrial and automotive production lines.

Challenges:

- Sensitivity to the environment: MIG welding requires a stable environment as the wind can disrupt the shielding gas, making it unsuitable for outdoor work without proper shielding.

- Cost: The equipment and the gas needed for MIG welding can be more expensive compared to stick welding.

Applications:

MIG welding is commonly used in automotive repair, manufacturing, and fabrication. It is ideal for welding thin to medium-thickness metals, including aluminum and steel.

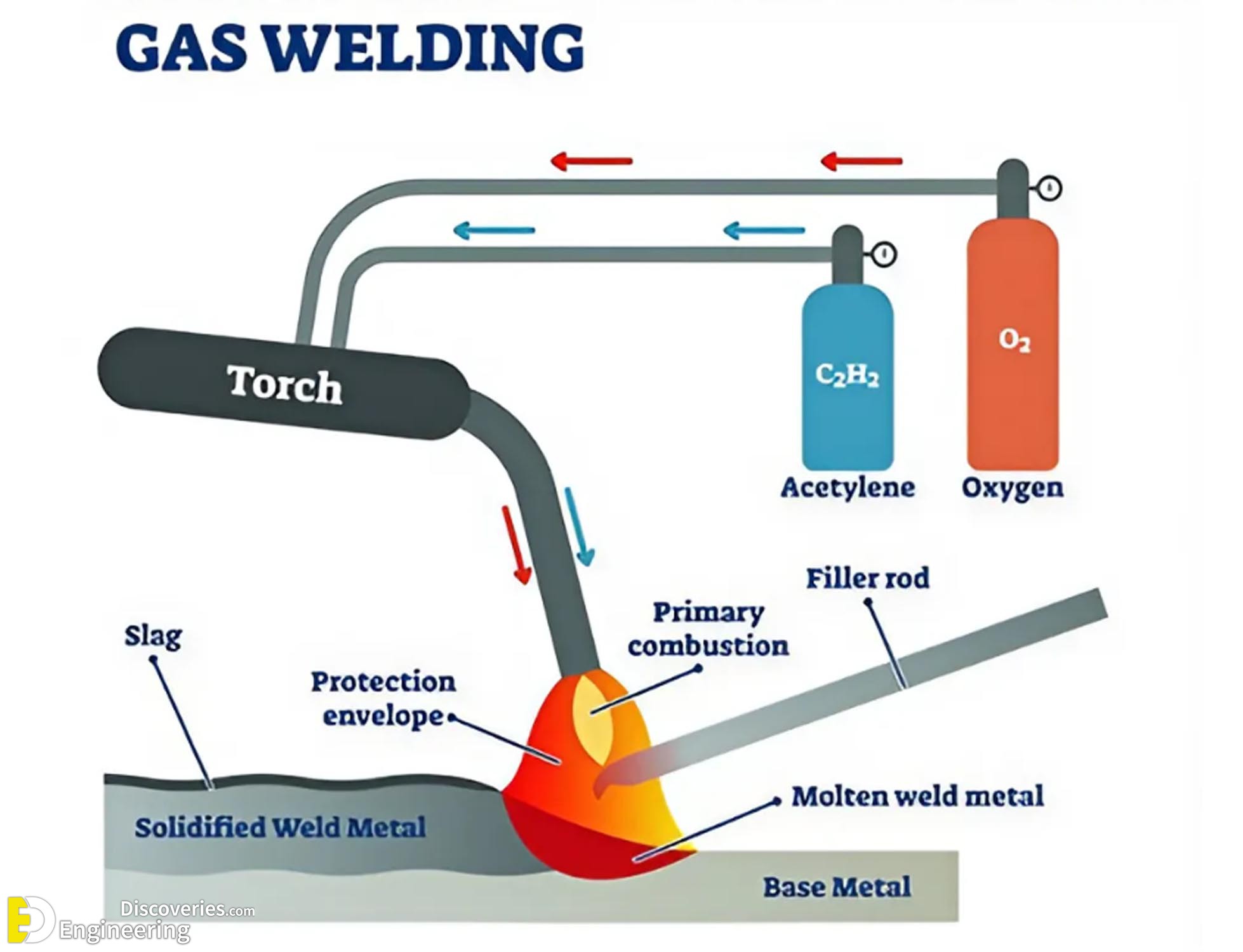

3. Gas Welding (Oxy-Fuel Welding – OFW)

Gas Welding, also known as Oxy-Fuel Welding (OFW), is one of the oldest methods of welding. It uses a flame produced by burning a mixture of oxygen and acetylene to heat and melt the materials to be joined. While gas welding has largely been replaced by more advanced methods, it still has specialized applications, particularly in repair and maintenance work.

Advantages of Gas Welding:

- Portability: Gas welding equipment is relatively portable, which makes it useful for fieldwork and repairs in hard-to-reach areas.

- Control: It allows for precise control over the heat and flame, which can be beneficial when working on thin metals.

Challenges:

- Slow process: Gas welding is generally slower compared to other welding techniques, which can limit its use in high-production environments.

- Less strength: The welds produced by gas welding are typically not as strong as those made by arc welding methods.

Applications:

Gas welding is most commonly used in repairing vehicles, maintenance of equipment, and metal art. It is particularly effective on thin sheets of metal and in situations where precision is more critical than speed.

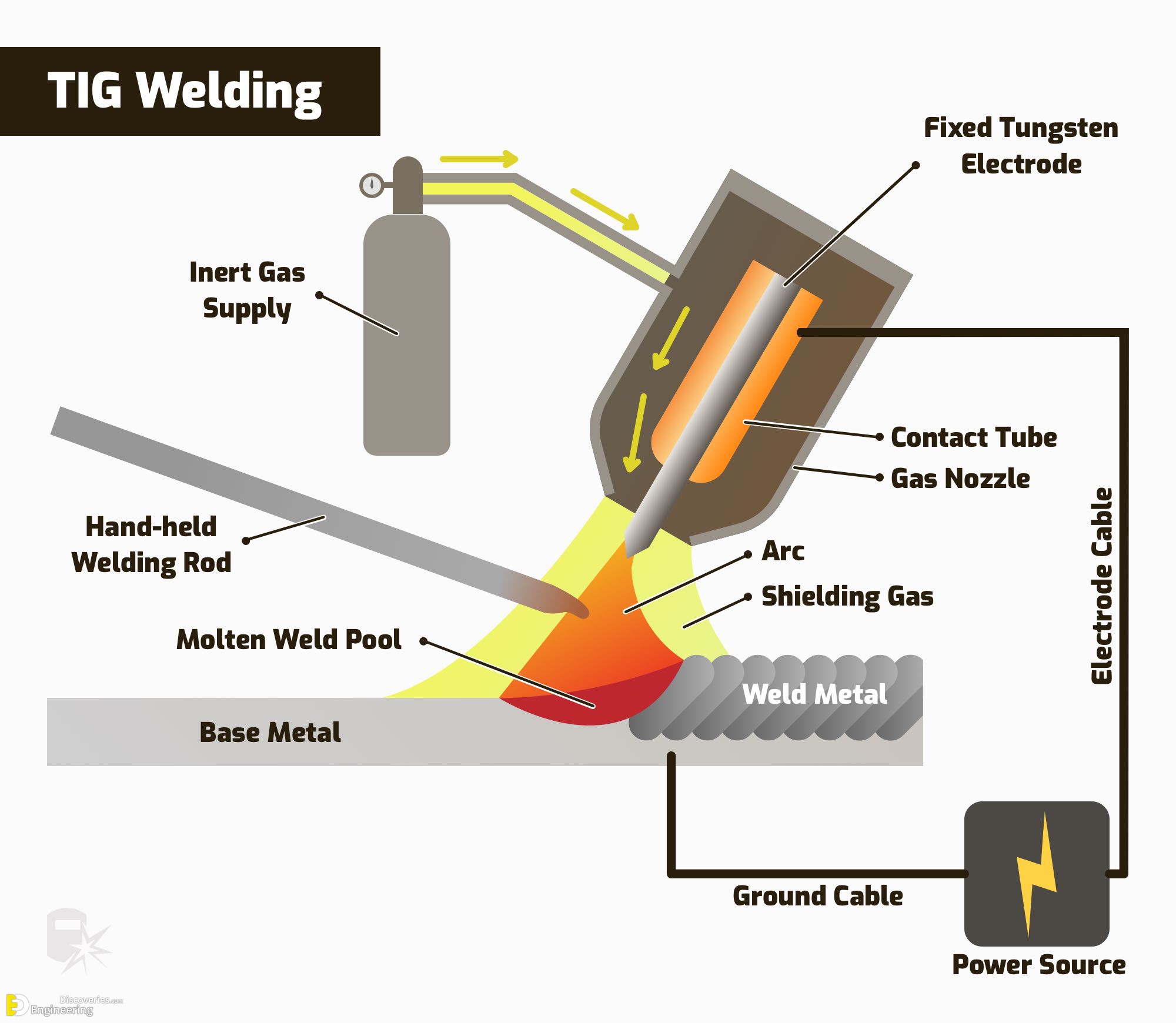

4. TIG Welding (Tungsten Inert Gas – GTAW)

TIG Welding, or Gas Tungsten Arc Welding (GTAW), is a highly precise welding process that uses a non-consumable tungsten electrode to produce the weld. Like MIG welding, a shielding gas, typically argon or helium, is used to protect the weld area from contamination. TIG welding requires significant skill and patience, but the results are often of the highest quality.

Advantages of TIG Welding:

- Precision: TIG welding offers superior control, allowing for precise, clean welds. This makes it ideal for delicate and intricate work.

- No spatter: Since there is no filler material used in most TIG welds, there is very little spatter, resulting in a clean finish.

- Strong welds: TIG welds are typically stronger and more durable than those produced by other methods, making them suitable for critical applications.

Challenges:

- Skill requirement: TIG welding is more difficult to learn and requires a higher level of expertise than MIG or stick welding.

- Slow process: Due to the high level of precision required, TIG welding can be slow, limiting its use in high-volume production environments.

Applications:

TIG welding is widely used in aerospace, automotive, and nuclear industries due to the strength and quality of the welds it produces. It is particularly effective for welding thin materials such as stainless steel and aluminum, and for projects where aesthetics and precision are paramount.

Welding, in all its forms, is a critical skill across various industries. Each welding process has its strengths and limitations, and selecting the right one depends on factors like material type, project environment, and desired output quality. Whether you need speed and efficiency for a high-production line or precision for delicate work, there is a welding method that suits your needs.