Welding is essentially a changeless joining process. It was characterized as ” A procedure of forever consolidating two metals with the utilization of heat”.Presently polymers can likewise be welded with various methods, along these lines it very well may be said as a joining procedure of two materials together with the use of warmth.Welding is a manufacture or sculptural process that joins materials, normally metals or thermoplastics, by causing combination,

which is particular from lower temperature metal-joining methods, for example, brazing and fastening, which don’t liquefy the base metal. Notwithstanding softening the base metal, a filler material is commonly added to the joint to frame a pool of liquid material (the weld pool) that cools to shape a joint that is normally more grounded than the base material.Pressure may likewise be utilized related to warm, or without anyone else’s input, to create a weld. The way toward welding can be ordered based on warmth age, notwithstanding the way toward welding which does not utilize warm to join as weight just is adequate for the trading of surface particles to make the joint.

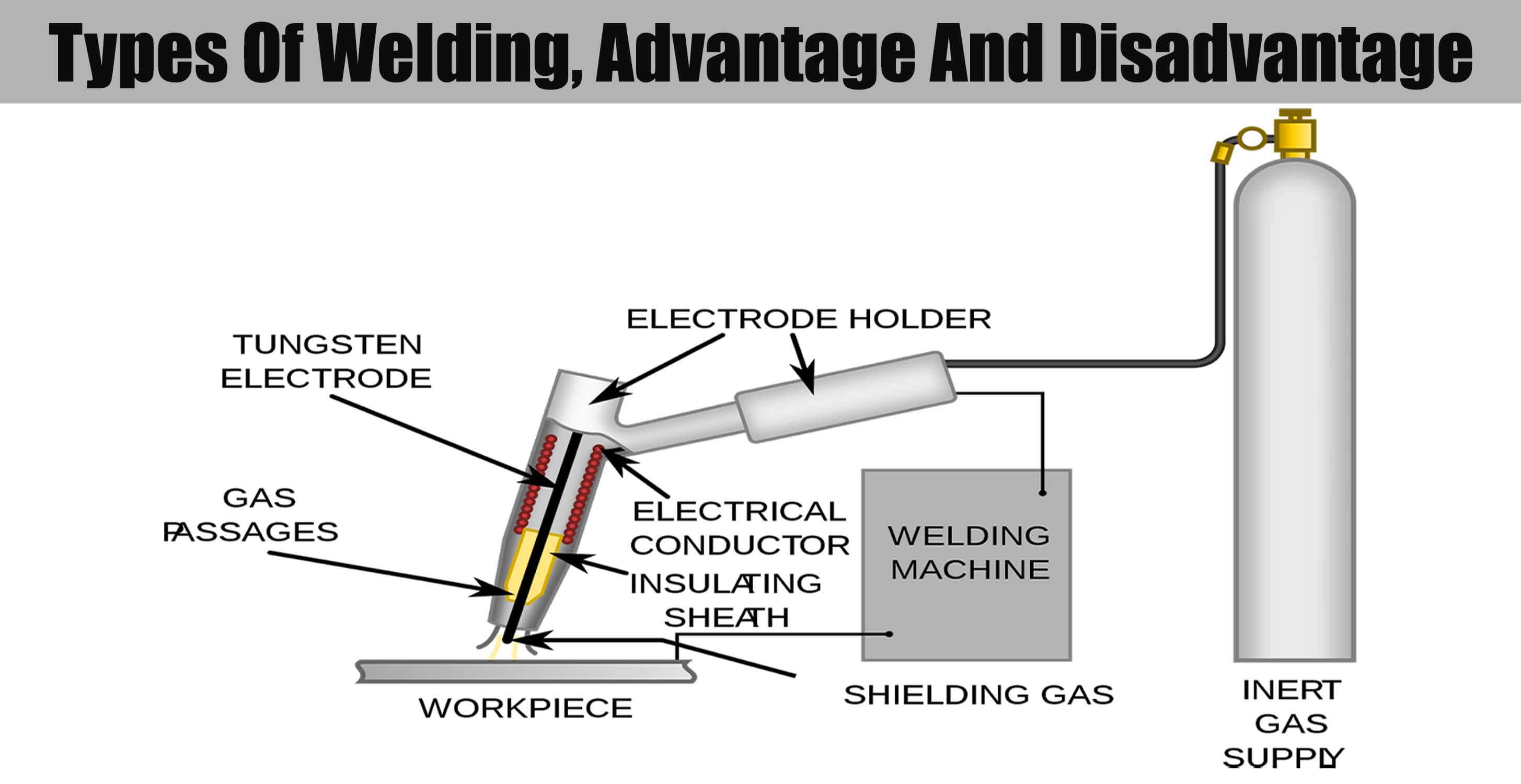

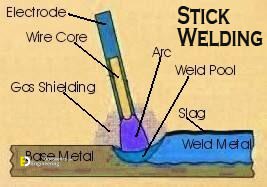

1- Stick welding

Stick welding is really basic and the stick welding machine is straightforward as well and furthermore truly shabby. You can purchase a Lincoln 225 AC welding machine at any Home Depot for route under 300 dollars.

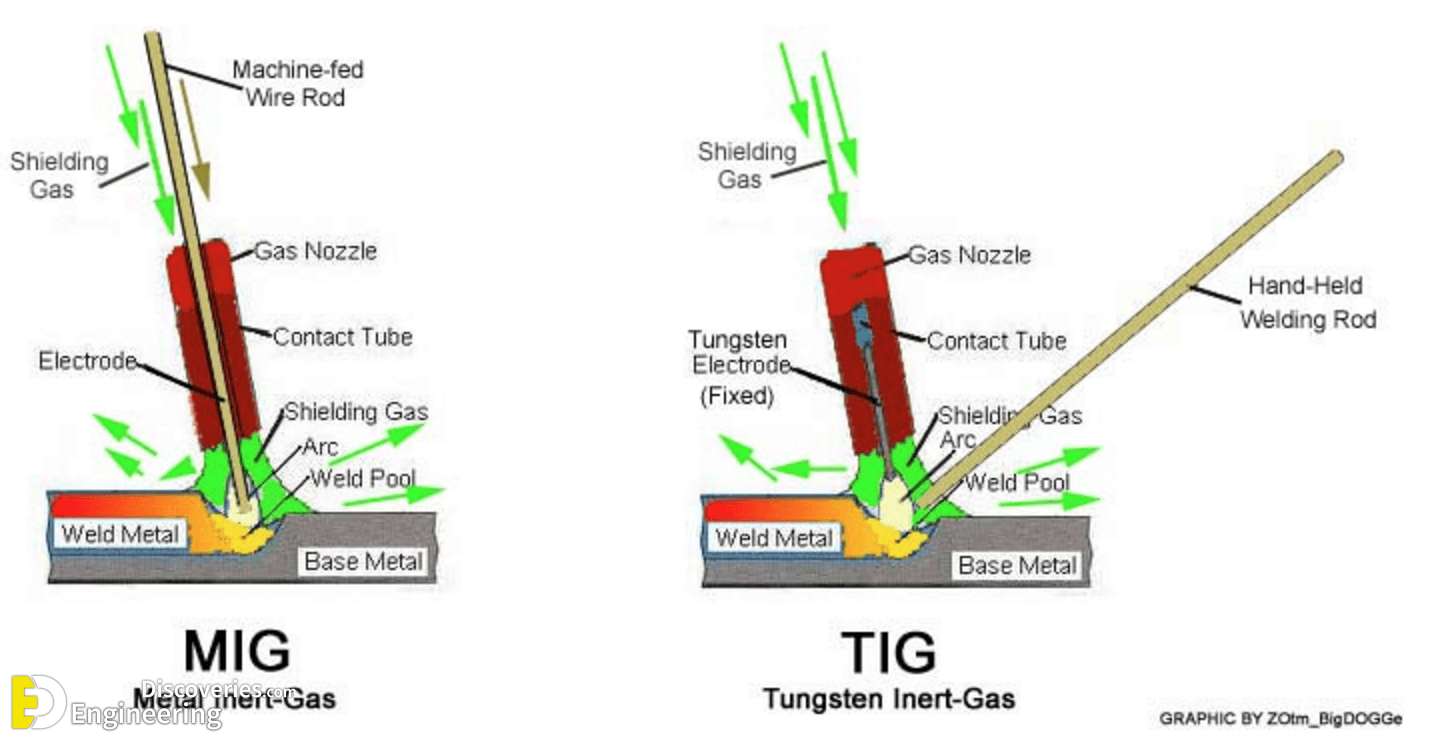

2- MIG welding

Mig welding is viewed as one of the most straightforward sorts of welding to learn. Why? Since the bar does not need to be nourished as it abbreviates like with stick welding. A wire is bolstered through a link and out the finish of the mig welding firearm and all the administrator is required to do is to pull the trigger and weld.

MIG likewise utilizes power yet rather than a filler pole it has a thin wire on a spool that is nourished through to a weapon, the power at that point warms that wire to weld the metal together. Oxy-Fuel utilizes a blend of a fuel gas and oxygen. There are different sorts of oxyfuel welding however essentially you would utilize something like accetlyn and oxygen.

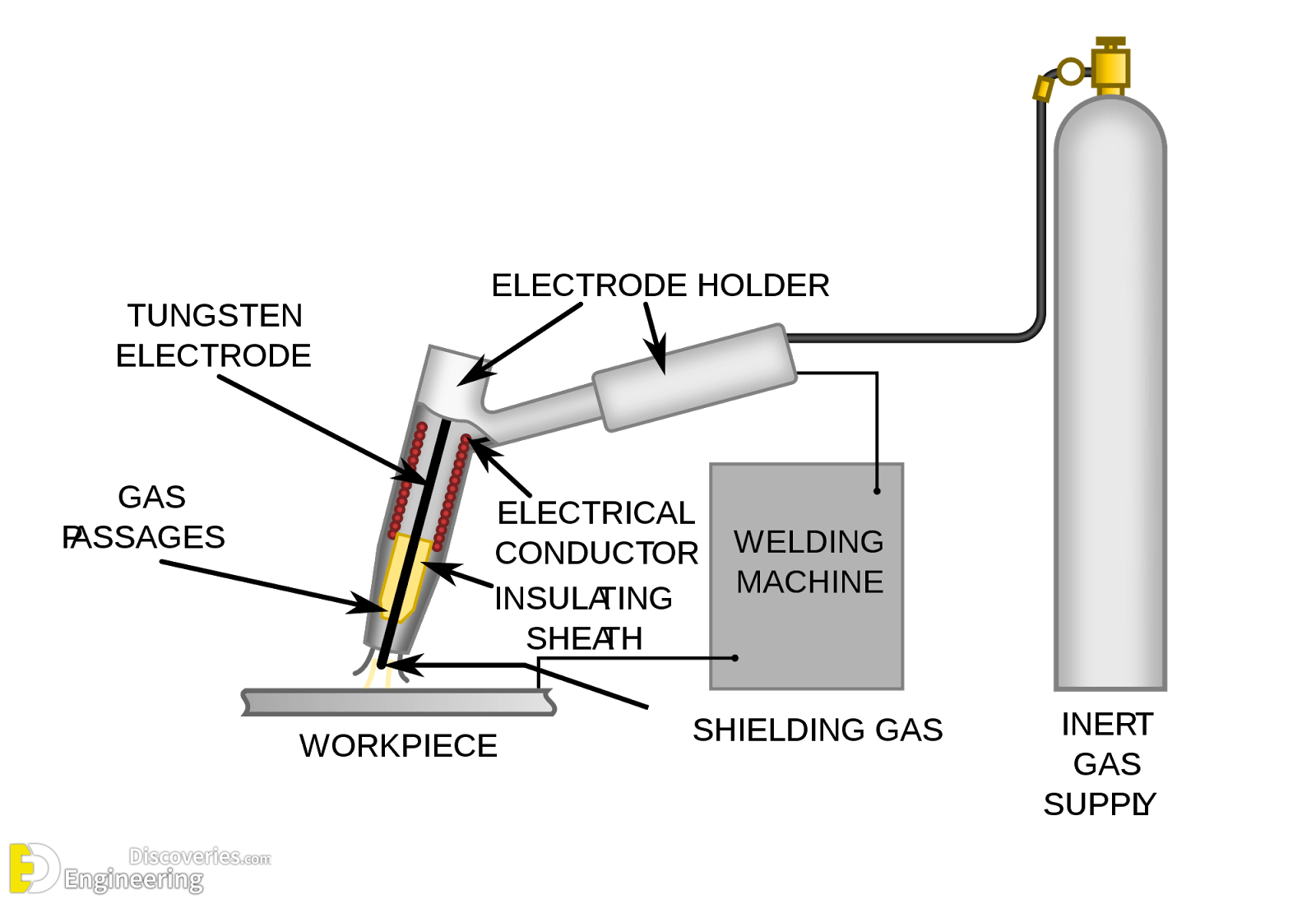

3- TIG welding

Tig welding is the most adaptable kind of welding of all. For all intents and purposes every traditional metal can be welded with the tig procedure. Carbon and low combination steels, treated steel, nickel amalgams, aluminum, magnesium, titanium, cobalt, and copper compounds would all be able to be welded utilizing this sort of welding. TIG additionally utilizes power to do the welding with a latent gas, for example, argon to keep the weld spotless and free from polluting influences. Tig likewise utilizes a filler bar to “weld” the 2 bits of metal together.

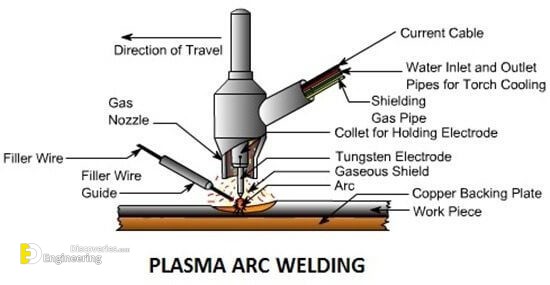

4- Plasma curve welding

Plasma curve welding is utilized where high accuracy is required and in circumstances where a recessed cathode is gainful. Plasma curve welding is utilized widely in aviation applications for dimensional rebuilding of air seals and fly motor edge fix where thicknesses are frequently underneath .015″ and amperages utilized are regularly single digit.

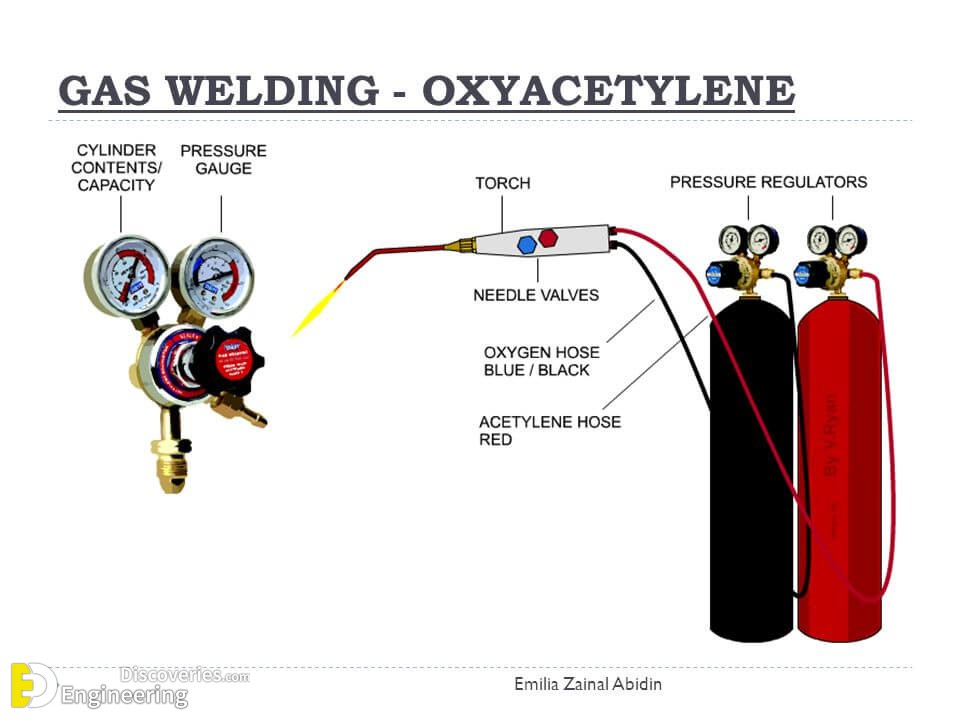

5- Gas welding

Gas welding is one of the old school sorts of welding. Oxygen and Acetylene is the most prominent setup for a gas welding pack and gas welding is as yet utilized a great deal for car fumes applications, and additionally by homebuilt plane aficionados for welding 4130 Chromoly tubing for plane fuselages. It works. It’s versatile.

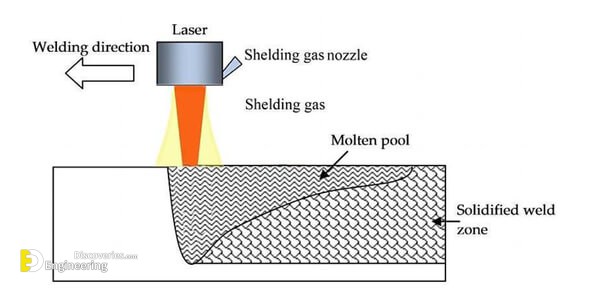

6- Electron bar and laser welding

Oxygen and Acetylene is the most well known setup for a gas welding unit and gas welding is as yet utilized a great deal for car fumes applications.

Advantages of Welding

1- No opening is required for welding

2- A lessened by and large load of the structure.

3- Less material is required.

4- It is more than that of the bolted joint.

5- The speed of manufacture is quicker in examination

Disadvantages of welding

1- Welded joints are increasingly weak and in this way their weariness quality is not exactly the individuals joined.

2- Because of uneven warming and cooling of the individuals amid the welding, the individuals may mutilate bringing about extra anxieties.

3- Gifted work and power are required for welding.

4- No arrangement for extension and compression is kept in welded association and in this way, there is a plausibility of racks.

5- The examination of welding work is more troublesome and costlier than the arresting work.

6- Imperfections like an inside air stash, slag consideration and fragmented infiltration are hard to identify.