Young’s Modulus, also known as the elastic modulus, is a fundamental concept in material science and engineering. It measures the stiffness of a material by describing the relationship between stress and strain. This modulus is essential in determining how materials deform under load, providing critical insights into their structural integrity.

Definition and Formula

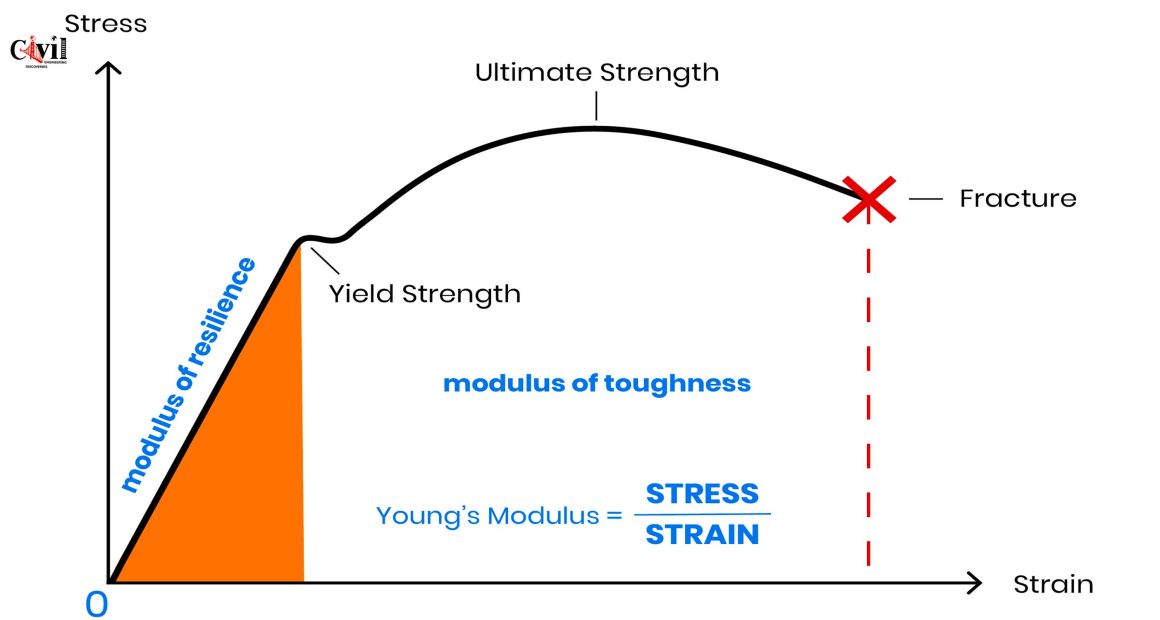

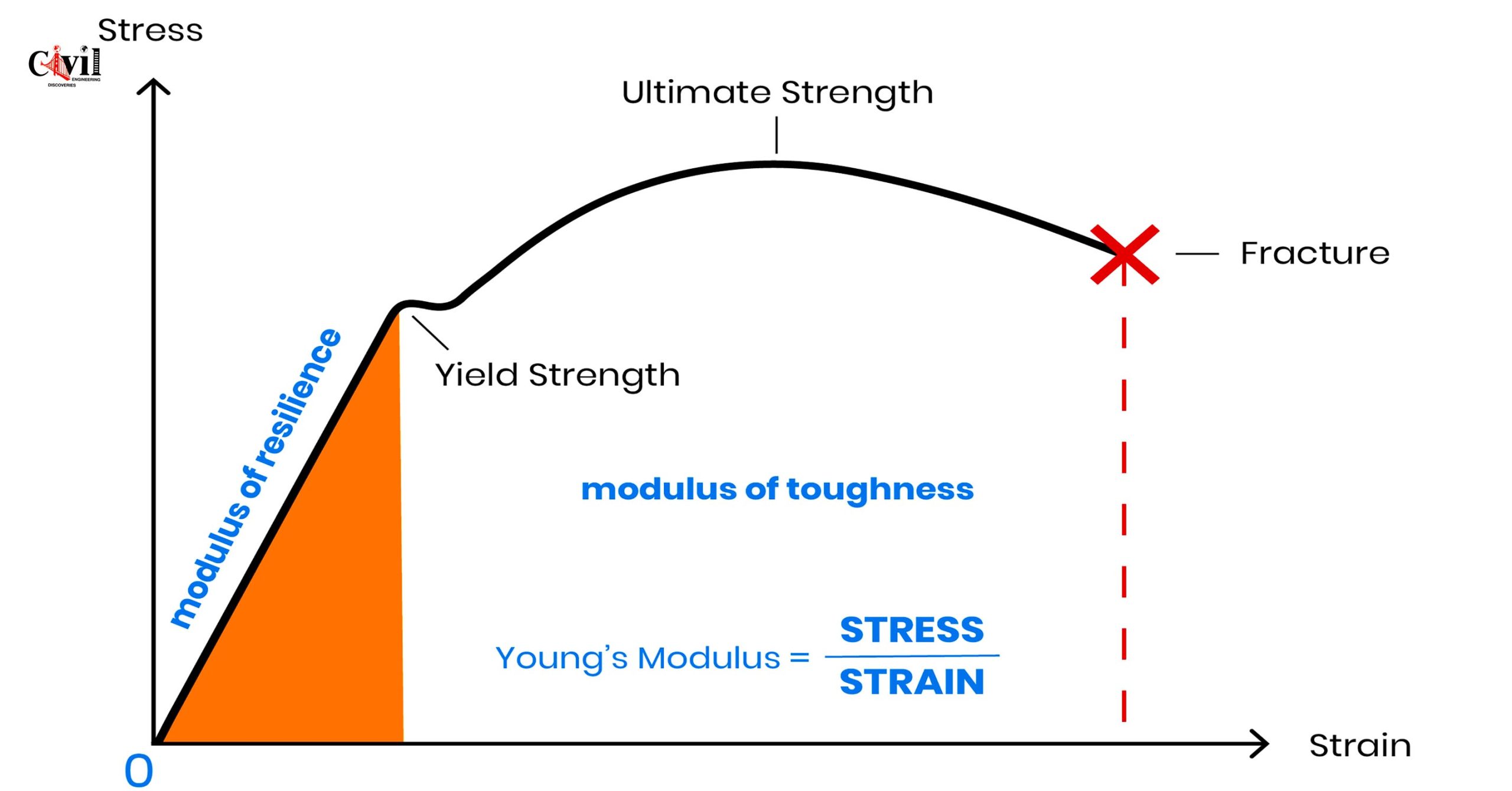

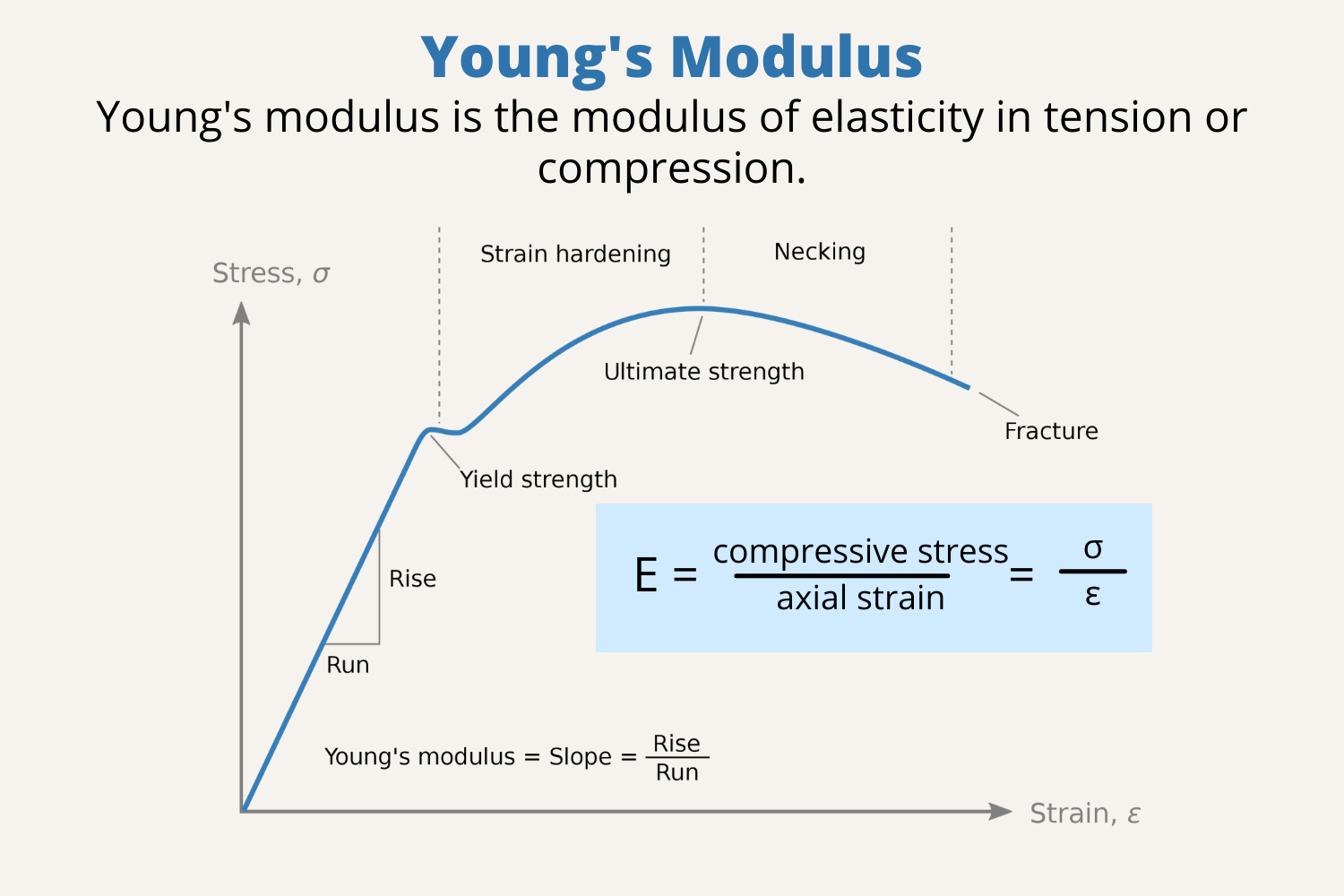

Young’s Modulus (E) is defined as the ratio of tensile stress (σ) to tensile strain (ε). Mathematically, the formula is expressed as:

E = σ / ε

In this equation, stress is the force applied per unit area, and strain is the relative deformation of the material. The modulus is typically measured in pascals (Pa) or gigapascals (GPa) for most materials.

Importance in Engineering and Construction

Young’s Modulus is vital in engineering, especially in construction and mechanical design. It helps engineers determine how much a material will stretch or compress when subjected to forces. Materials with high Young’s Modulus, such as steel, are stiffer and deform less under load, making them ideal for structural applications. On the other hand, materials with a lower modulus, like rubber, are more flexible.

Factors Affecting Young’s Modulus

Various factors influence the value of Young’s Modulus in a material. These include:

- Material Composition: Different materials exhibit different stiffness levels. Metals tend to have higher Young’s Modulus values, while polymers and elastomers have lower values.

- Temperature: The modulus decreases with increasing temperature as materials become more flexible when heated.

- Microstructure: The arrangement of atoms and molecules within a material affects its mechanical properties. For example, crystalline structures typically have higher Young’s Modulus than amorphous ones.

Applications of Young’s Modulus

Young’s Modulus is crucial in various fields. Here are some common applications:

- Civil Engineering: Used to design bridges, buildings, and roads to ensure they can withstand loads without excessive deformation.

- Mechanical Engineering: Helps in selecting appropriate materials for machine parts, ensuring they operate efficiently under stress.

- Aerospace Industry: Determines the stiffness of materials used in aircraft and spacecraft, which is vital for maintaining safety and performance.

- Medical Implants: Engineers use Young’s Modulus to match materials for medical implants, such as bone plates and screws, to ensure compatibility with human tissues.

Comparison of Young’s Modulus in Different Materials

Here’s a comparison of Young’s Modulus values for common materials:

- Steel: 200 GPa

- Aluminum: 70 GPa

- Glass: 50-90 GPa

- Rubber: 0.01-0.1 GPa

These values highlight how steel, with its high modulus, is far stiffer than rubber, which is why it’s commonly used in structural applications.

Click Here To See How Steel Reinforcement Strengthens Concrete Structures