Workability is a property of fresh concrete that determines the ease and homogeneity with which it can be mixed, placed, consolidated, and finished. It is a complex property that is affected by many factors, including the water/cement ratio, the type and grading of the aggregates, the use of admixtures, and the temperature of the concrete.

The workability of concrete is important for a number of reasons. First, it affects the ease with which the concrete can be placed and consolidated. This is important for ensuring that the concrete is properly compacted, which is essential for achieving its full strength potential. Second, the workability of concrete affects the findability of the concrete. A more workable concrete will be easier to finish, which can result in a smoother and more attractive surface. Third, the workability of concrete can affect the segregation of the concrete. Segregation is the separation of the different components of the concrete, which can lead to weak and brittle concrete.

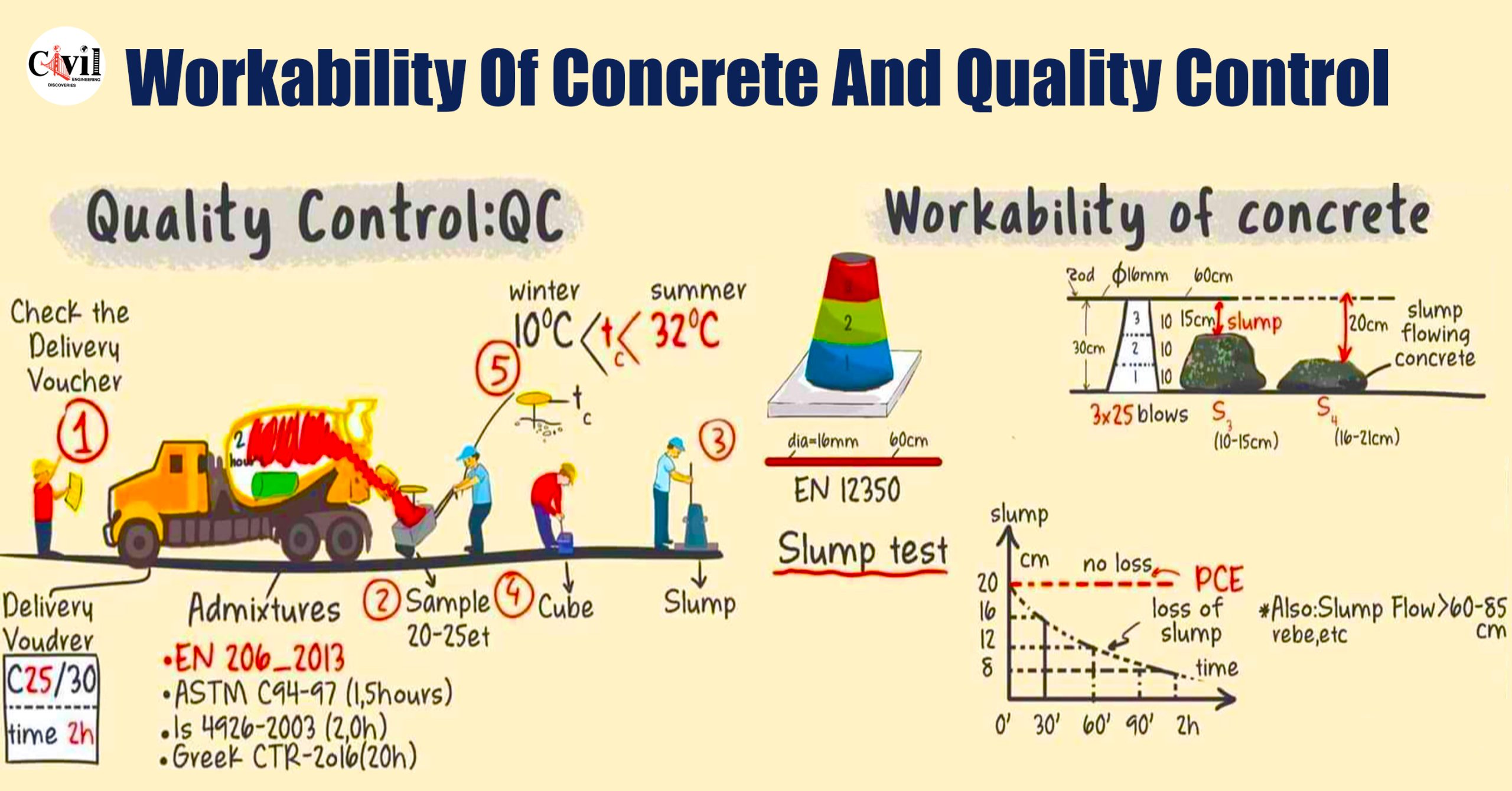

There are a number of ways to measure the workability of concrete. One common method is the slump test. The slump test measures the amount of slump, or flow, of the concrete. Concrete with a high slump is more workable than concrete with a low slump. Other methods of measuring workability include the flow table test, the Vee-Bee test, and the L-Box test.

The desired workability of concrete will vary depending on the specific application. For example, concrete that is being used to cast a large, monolithic structure will need to be more workable than concrete that is being used to cast a small, intricate form.

The workability of concrete can be affected by a number of factors, including the following:

- Water/cement ratio: The water/cement ratio is the most important factor affecting the workability of concrete. A higher water/cement ratio will result in a more workable concrete, but it will also reduce the strength of the concrete.

- Type and grading of aggregates: The type and grading of the aggregates can also affect the workability of concrete. Coarser aggregates will make the concrete more workable, while finer aggregates will make the concrete less workable.

- Use of admixtures: Admixtures can be used to improve the workability of concrete. Air-entraining admixtures, for example, can increase the workability of concrete without increasing the water/cement ratio.

- Temperature of concrete: The temperature of the concrete can also affect its workability. Concrete that is colder will be less work than concrete that is warmer.

The workability of concrete is an important property that affects the ease of placing, consolidating, and finishing the concrete. It is also important for ensuring that the concrete achieves its full strength potential. The workability of concrete can be affected by a number of factors, including the water/cement ratio, the type and grading of the aggregates, the use of admixtures, and the temperature of the concrete.

Click Here To See Concrete Slump Test Definition, Procedure And Types Of Slump Test