One of the most crucial aspects of construction projects is determining the quantity of bricks required for efficient material management. A tractor trolley is commonly used for transporting bulk bricks, and understanding its capacity can help plan logistics effectively.

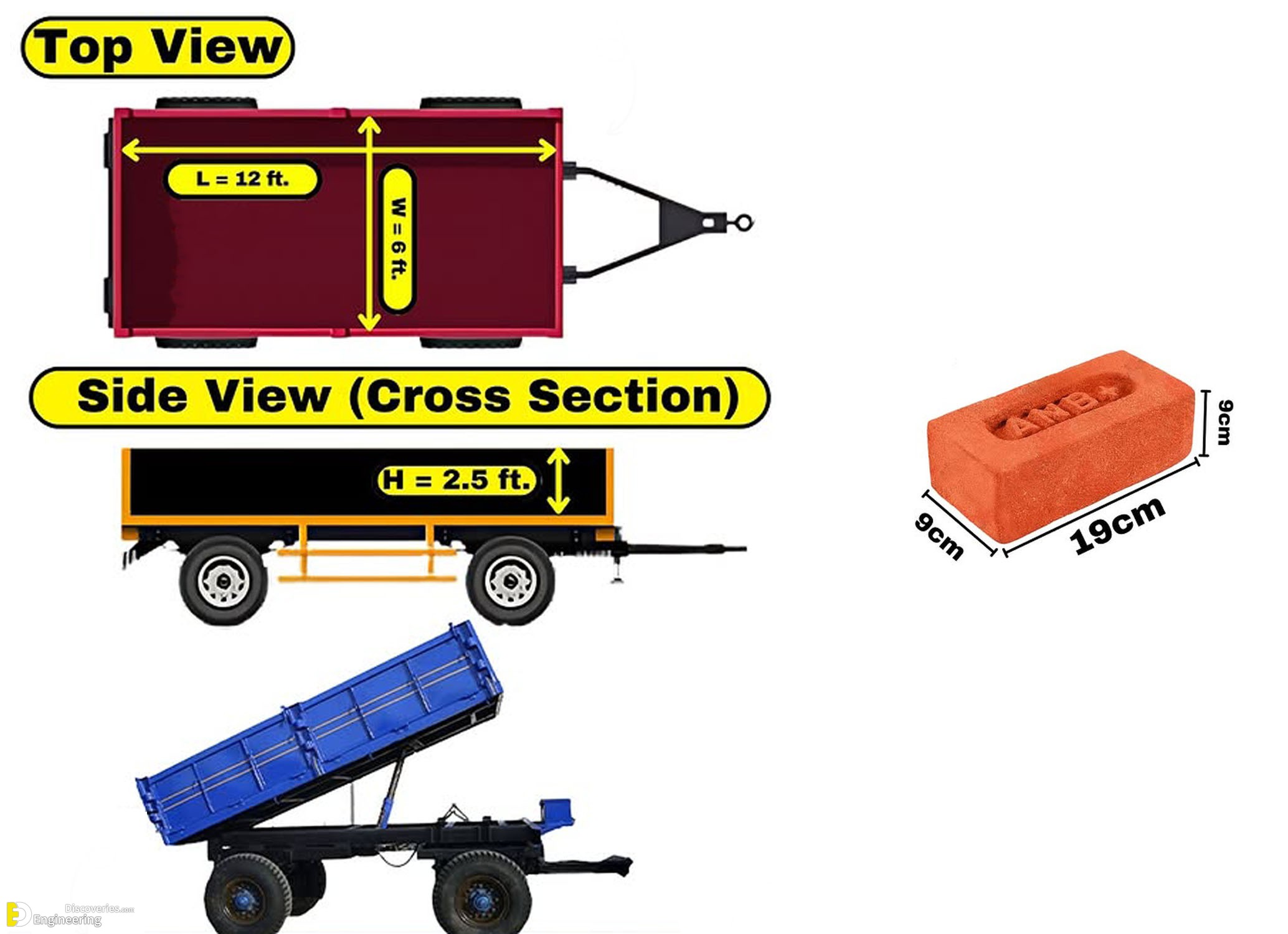

Given Data

Trolley Dimensions:

Length = 12 feet

Width = 6 feet

Height = 2.5 feet

Step 1: Calculate the Volume of the Trolley

Volume (V) = Length × Width × Height

= 12 ft × 6 ft × 2.5 ft = 180 cubic feet

Step 2: Convert Volume to Cubic Meters

We know that 1 cubic foot = 0.0283 cubic meters

So,

180 × 0.0283 = 5.094 cubic meters

Step 3: Calculate the Volume of One Brick

Brick Dimensions:

Length = 190 mm = 0.190 m

Width = 90 mm = 0.090 m

Height = 90 mm = 0.090 m

Volume of One Brick = Length × Width × Height

= 0.190 m × 0.090 m × 0.090 m = 0.001539 cubic meters

Step 4: Calculate the Number of Bricks in the Trolley

Number of Bricks = (Trolley Volume / Volume of One Brick)

= 5.094 / 0.001539 = 3,310 bricks (approximately)

Factors Affecting the Number of Bricks in a Trolley

While the above calculation provides an estimate, real-world conditions can impact the actual quantity. Several factors influence the number of bricks that can be loaded in a trolley:

1. Arrangement of Bricks

The stacking pattern of bricks significantly affects how many can fit into the trolley. Properly arranged bricks with minimal gaps maximize capacity, while haphazard stacking reduces efficiency.

2. Type of Bricks

Different bricks have varying sizes and densities. If hollow bricks or concrete blocks are used instead of standard clay bricks, the quantity will differ.

3. Moisture and Weight Considerations

Bricks absorb moisture, which adds weight. A fully loaded trolley may not carry the same number of bricks if weight limits are exceeded.

4. Shape and Size Variations

Bricks from different manufacturers may have slight dimensional variations. These small differences can affect the total count when stacked in bulk.

How to Optimize Brick Transportation in a Tractor Trolley

Efficiently managing the transportation of bricks can save both time and cost. Here are some best practices to follow:

1. Proper Stacking

- Use a uniform stacking pattern to minimize air gaps.

- Arrange bricks in an interlocking manner to improve stability during transportation.

2. Load Balancing

- Ensure even weight distribution across the trolley to avoid tipping over.

- Avoid overloading to prevent damage to both the bricks and the trolley.

3. Cover the Load

- Use a tarpaulin sheet to protect bricks from rain or excessive dust.

- This prevents moisture absorption, which can weaken bricks.

4. Plan Transportation Routes

- Choose smooth, accessible roads to avoid excessive jolting that can cause breakage.

- If transporting to a distant site, secure the load properly.

Click Here To See How To Calculate The Quantity Of Cement, Sand, And Bricks For 1 Cubic Meter