Pre-tension Concrete

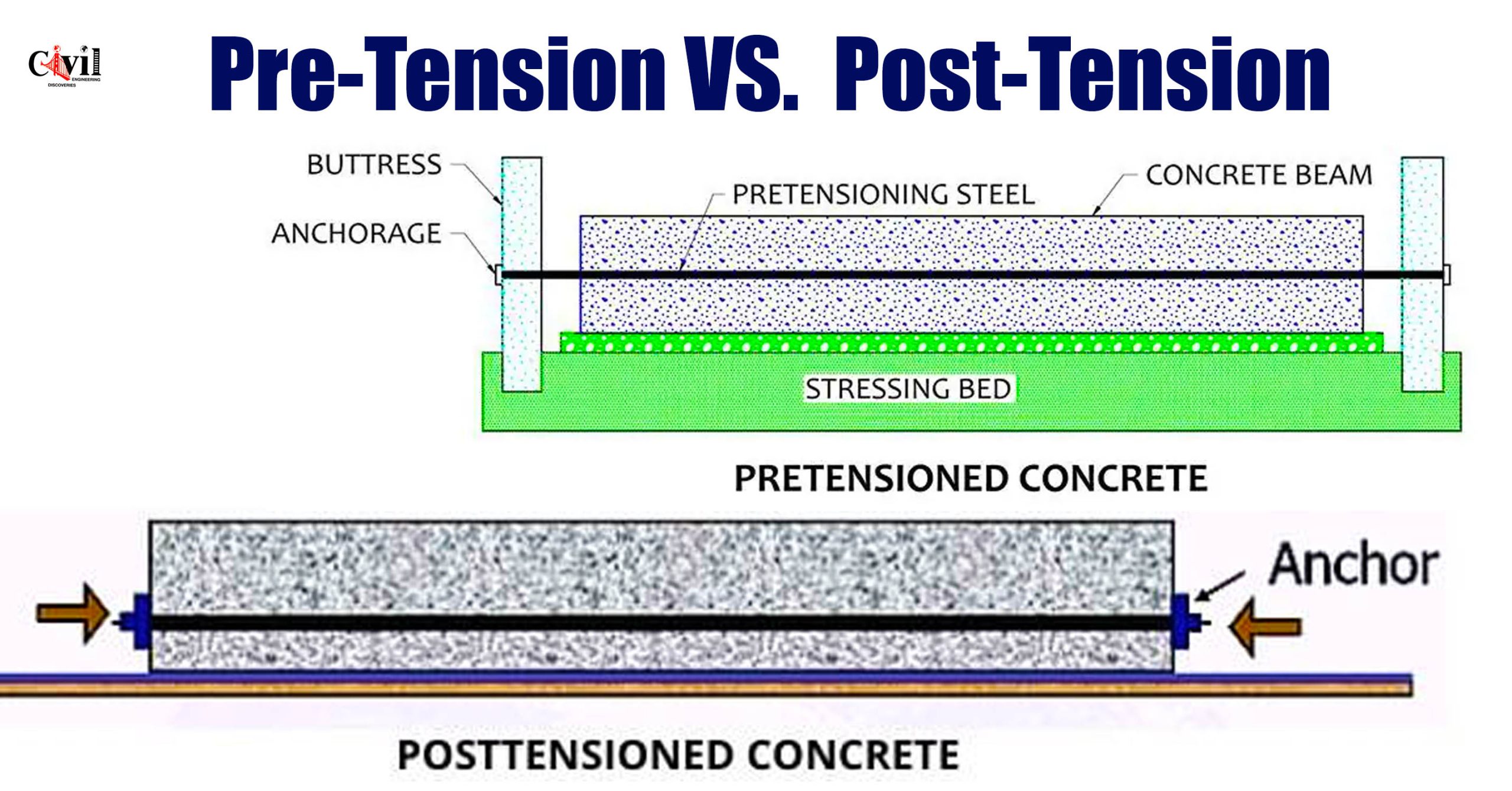

Pretension in concrete is a method that involves the use of tendons to prestress the concrete before it is placed. It is a suitable method for small structural elements and the pre-tensioning members are produced in the mold.

To pretension concrete, the steel is first tensioned in a frame or between anchorages that are external to the member. The concrete is then cast around the steel. After the concrete has developed sufficient strength, the tension is slowly released from the frame or anchorage, transferring the stress to the concrete to which the tendons have become bonded. The force is transmitted to the concrete over a certain distance from each end of a member, which is known as the transfer length.

Post-tension Concrete

Post-tensioning is a method used in concrete structures where the prestressing process is carried out after the concrete has gained sufficient strength. This technique is suitable for heavy structures and it was developed for better load-bearing capacity.

To create post-tensioned concrete, ducts are cast into the concrete through which tendons can be threaded. Alternatively, tendons can be encased in a plastic sleeve or greased and then cast in concrete.

Once the concrete has gained enough strength, the tendons are tensioned using portable jacks. The load is transmitted to the concrete through permanent anchorages embedded in the concrete at the ends of the tendons.

Later, the ducts are usually filled with grease or grouted to protect the tendons against corrosion. In some cases, post-tensioning tendons run alongside the concrete member.

Pre-tension Concrete vs Post-tension Concrete

| Sr.No | Pretensioning | Post-tensioning |

| 1 | Pretension is the technique in which we impart tension in strands before placing the concrete. | Post-tensioning is done by forming a duct in which strands are pulled (tensioned) after the concrete gains its full strength. |

| 2 | In this type of concrete, the pre-stressing cables called the strands are tensioned before casting the concrete and then concrete is cast enclosing the tensioned cables. | In this type of concrete, the strands are enclosed within a duct in the form and then concrete is cast. The process of tensioning the strands is carried out after the concrete attains its sufficient strength. |

| 3 | Post-tension Concrete | In this method, products are changed according to a structure. |

| 4 | Pre-tensioning members are produced in a mold. | Cables are used in place of wires and jacks are used for stretching. |

| 5 | It is cheaper because the cost of sheathing is not involved in pre-tensioning | It is costlier because the cost of sheathing is required. |

| 6 | Pre-tensioning is preferred when the structural element is small and easy to transport | Post-tensioning is preferred when the structural element is heavy. |

| 7 | Loss of prestressing isn’t less (about 18 %) | Loss of prestressing isn’t more (about 15 %) |

| 8 | Small sections are to be constructed | The size of a member is not restricted, long-span bridges are constructed by post-tensioning |

| 9 | It is more reliable and durable | The durability depends upon the two anchorage mechanism |

Click Here To See Advantages And Disadvantages Of Prestressed Concrete